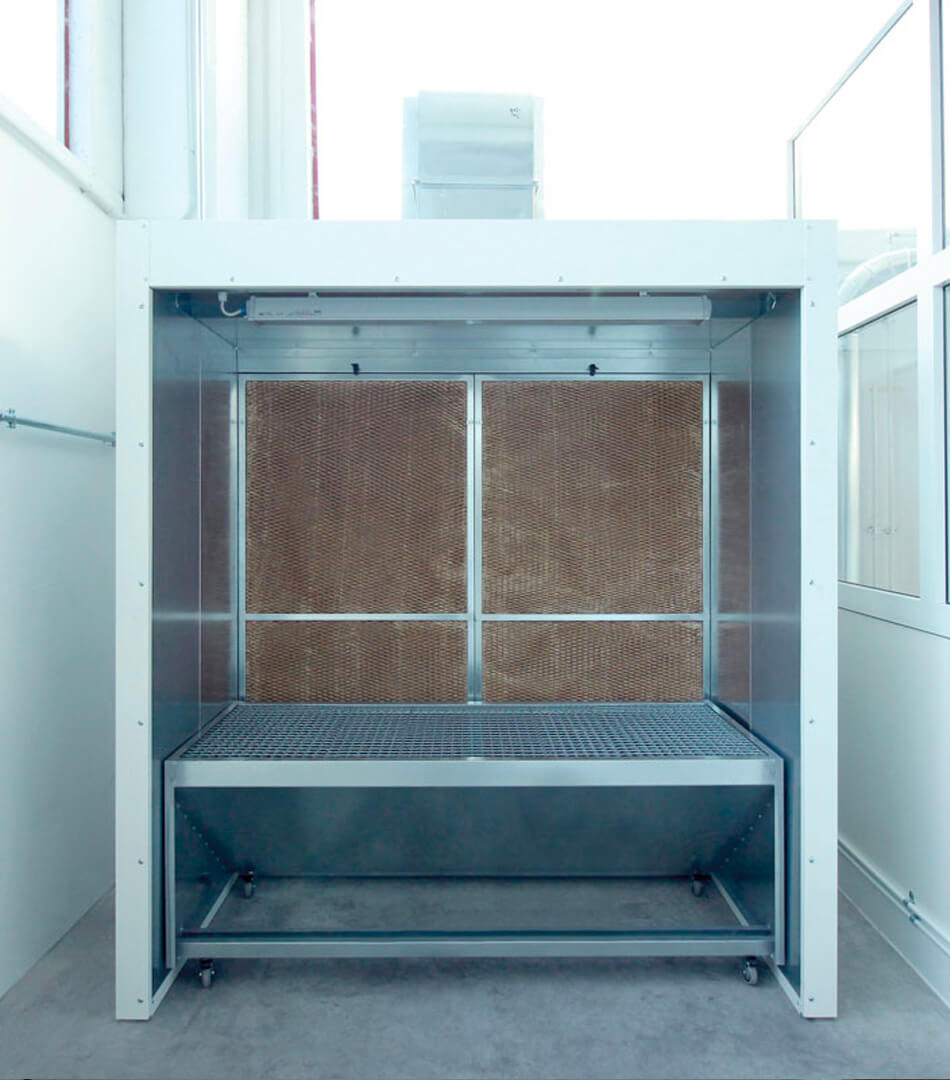

Cabina di verniciatura con filtrazione a secco

La cabina di verniciatura con filtrazione a secco è costituita da una struttura autoportante realizzata con pannelli in lamiera zincata presso-piegata uniti tra loro, adatta per la verniciatura ad acqua o solvente di pezzi di varie dimensioni, per piccole serie o ritocchi.

Monitoraggio intasamento

Miglior apporto qualità/prezzo

Componenti forniti a norma ATEX

Nella parte superiore della cabina di verniciatura a secco è posto un sistema di aspirazione composto da uno o più ventilatori centrifughi con girante interna a pale rovesce, che garantiscono elevati rendimenti di aspirazione e bassa rumorosità.

L’aria (carica di particelle inquinanti) aspirata dalla cabina di verniciatura con filtrazione a secco viene filtrata mediante un sistema di filtrazione a secco, composto da un primo stadio di filtri in cartone a doppio labirinto inerziale e da un secondo stadio con materassino in fibra di vetro.

Prodotto adatto per: Metallo Plastica Legno

/01 Recupero in depressione dell'aria aspirata.

/03 Sistema elettronico (inverter) di regolazione della portata d’aria aspirata.

/02 Tubazione di espulsione e/o ripresa aria.

/04 Sensore di flusso per attivare la cabina solo durante la spruzzatura.

I vantaggi della cabina di verniciatura con filtrazione a secco:

MONITORAGGIO INTASAMENTO

Il graduale intasamento dei filtri viene indicato da un sistema visivo a liquido o tramite il segnale automatico di un pressostato differenziale.

COMPONENTI FORNITI A NORMATIVA ATEX

Dove necessario i componenti (aspiratore, plafoniere ecc.) della cabina di verniciatura con filtrazione a secco vengono forniti a normativa ATEX.

MIGLIOR Rwp-contentORTO QUALITÀ/PREZZO

Il principio di funzionamento semplice ed efficace e la struttura in lamiera, consentono un prezzo economicamente molto competitivo.

CONTATTI